Hey everyone 👋

You hear about Intel, NVIDIA, and AMD almost every day - new chips, fresh launches, billion-dollar bets.

Right after we did a deep dive on Intel, news broke that NVIDIA is partnering with them for integrated graphics. The headline? NVIDIA just bought 5% of Intel - roughly $5 billion worth of shares - right after Uncle Sam poured in $10 billion a couple of weeks ago.

We’re even hearing rumors of Apple wanting to “make Intel rich again,” though nothing’s confirmed yet. What is confirmed is that Intel and NVIDIA are collaborating on custom x86 processors that will power NVIDIA’s AI infrastructure, with talk of Intel chips featuring NVIDIA RTX-class graphics coming down the line.

It’s a fascinating story - but not the most important one.

The headlines can’t get enough of Big Tech but their tech is something that is largely dependent on just this one company - from Apple iPhones to Amazon’s Cloud.

Today’s deep dive is about that giant - Taiwan Semiconductor Manufacturing Company (TSMC) - the company that quietly powers everything from your smartphone to the AI arms race itself.

When we think of tech companies, Google, Meta, Microsoft and other similar companies are some of the popular ones that come to mind.

The Big Tech is pretty big and there is no denying its importance but there is a company that is almost invisible from popular discourse that is powering most of the Big Tech.

Yet, we rarely hear mention of that company that is single-handedly powering not just Big Tech and most of the technology around us.

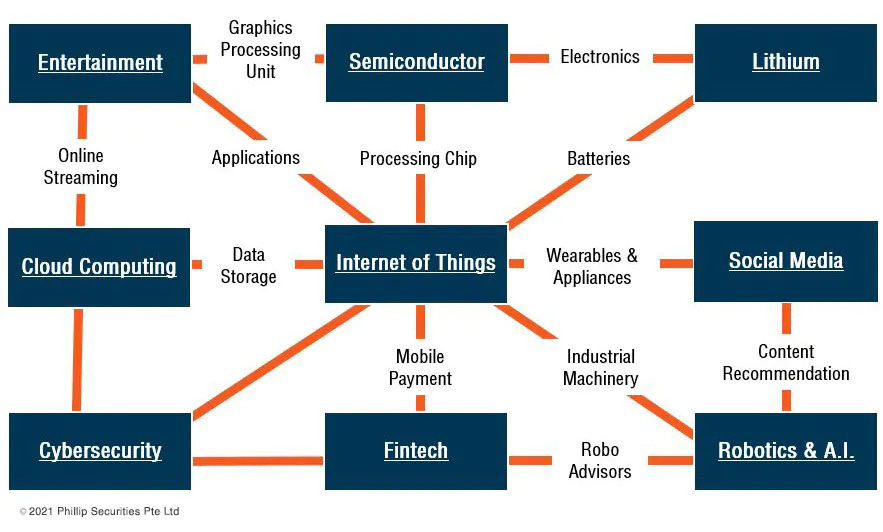

This invisible powerhouse powers everything from consumer electronics like smartphones & laptops to military technology like drones & radars and critical infrastructure like hospitals, banks, power-grids - basically anything critical that you could think of.

Apart from the technological side of things, this company is also at the heart of global politics and a potential global conflict. The two superpowers of our time - China and the USA have their sleeves rolled-up over this company.

That’s why I feel it’s the perfect time to discuss Taiwan Semiconductor Manufacturing Company (TSMC) and learn what it does, how it does it and why it is so important for the world.

Before We Begin

Before I take you on a deep-dive of TSMC and its origins, let’s first spend a couple of minutes discussing the technical terms that I will keep on repeating in this piece.

Once we have a baseline knowledge of these smaller topics, it would be easier for most people to understand what I’m blabbering about in the rest of this piece.

Depending on how familiar you already are with all of this, you may choose to skim through or skip this section.

What are Chips?

In our context, a chip is a small electronic device that is the brain for any digital device you could think of. Any electronic device that can be programmed has a chip inside it.

Chips are tiny pieces of silicon with the ability to turn electrical signals into logic that we can further use to perform calculations.

You interact with chips everyday without even knowing most of the time. Even right now, the device you’re using to read this article has a chip.

At a personal level, anything from your laptop, computer, car, etc includes a semiconductor chip in one form or another.

At a grand level, fighter jets, submarines, large data-centers, all have chips that allow these devices to perform complex operations.

So, no matter if a device is big or small, if it is smart in any way, it is being powered by chips. They are the building blocks for any digital device.

There is no escaping these chips. You find them in your home, inside hospitals, airports, banks - basically everywhere.

Now, chips come in many shapes and sizes, and that’s why people have different names for them.

Chips are commonly referred to as Microprocessors, Integrated Circuits (ICs), CPUs, GPUs.

The terms above have some slight differences but for today, we’ll assume that all of them are the same thing - Chips.

What’s a Foundry?

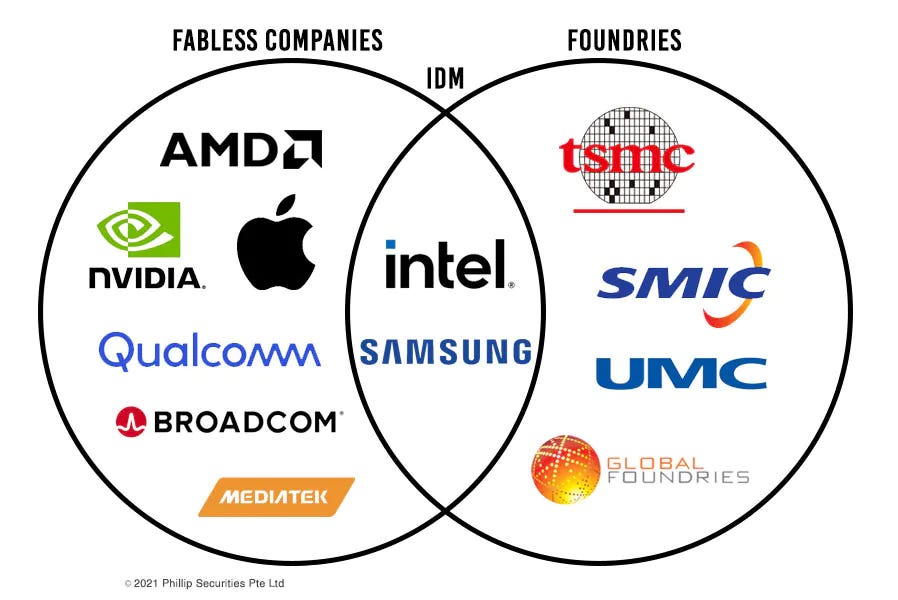

Foundry is a company that manufactures semiconductor chips. Other companies come to foundries with their designs to get chips according to their needs.

These are expensive factories where some of humanity’s most cutting edge engineering happens. If you ever see a foundry, it looks like an alien facility.

You’d see humans dressed up in special suits wandering around with specialized robots around them, moving to and from the big machines that build chips.

Fabs are so expensive that setting up a new fab can cost you anywhere from $1-20 billion.

The chip manufacturing process involves hundreds of steps and can take months from design to production.

Humans aren’t even allowed to enter without first going through a series of specialized chambers that first clean and isolate the human body from the rest of the environment.

These facilities have to be really clean, so clean that the smallest speck of dust can ruin a whole chip.

Foundries have to usually maintain an air quality that is 10,000 times cleaner than the outside air.

So, foundries are basically chip makers that are contracted by other companies to build out chips based on their designs.

Foundries are also called Fabrication plants or Fabs for short.

What Does TSMC Do?

TSMC is an independent semiconductor foundry, and not just any foundry but the most advanced foundry in the entire world. TSMC was the first company to solely focus on chip manufacturing of the world’s most advanced semiconductors.

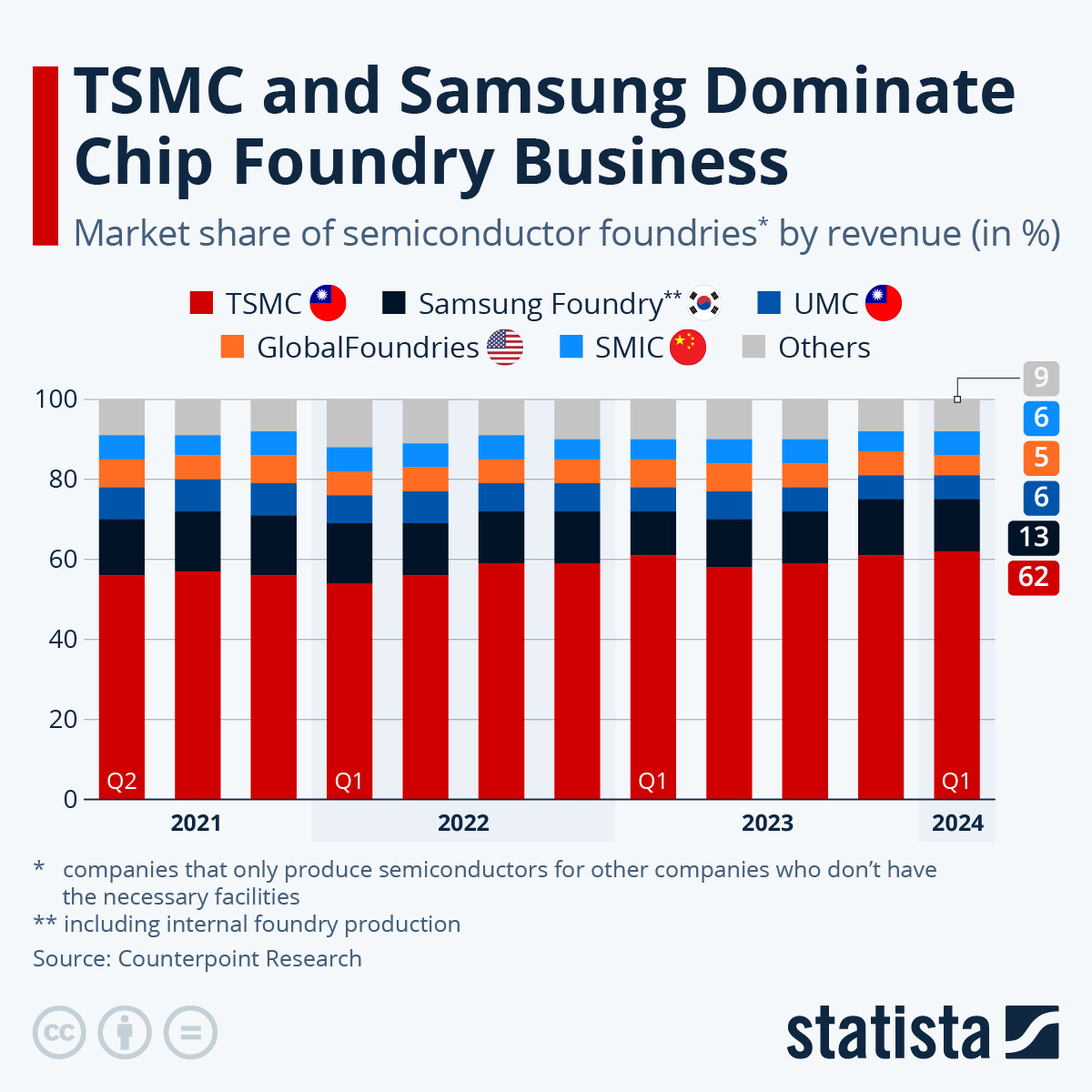

TSMC is the world’s largest contract chipmaker producing more than 60% of the world’s semiconductors and over 90% of the most cutting-edge chips.

Every tech company that you can think of is somehow related to TSMC. Big tech companies like Apple, Nvidia, AMD, Tesla, etc are the direct customers of TSMC.

Companies like AMD and Nvidia directly share their chip designs with TSMC to get their chips manufactured. Same goes with Apple, Tesla and many others.

From the phone in your hand, the laptop at your office to your PlayStation and the sound system of your car - pretty much all of them use chips produced by TSMC

Moreover, any other company that is providing a digital service to you is probably using TSMC’s chips - think of Youtube, Netflix, ChatGPT or pretty much any of your favorite sites.

It boggles my mind that such a significant percentage of our digital world depends on just one company.

The 2020-2023 supply chain shortage didn’t just hurt TSMC but in-turn disrupted the entire operations of the digital world.

The Taiwanese government is the single largest shareholder of TSMC with the stock amounting to ~30% of the country’s stock market index.

Foreign investors hold the majority of the company. In 2022, the company exported $184 billion worth of chips.

TSMC is so significant that it is talked about that the next World War may just happen to get ahold of the technology they produce.

The two superpowers China and USA have their interests in TSMC and both have their eyes on the small country.

The Origins of TSMC

The origin story of TSMC is quite surprising, coming from a country struggling with low-value exports and a poor economy. I’ll discuss some of the most important events in the TSMC origin story below:

Taiwan’s Interest in Semiconductors

Taiwan wasn’t a country known for high-tech exports a couple of decades back. It was a small country facing economic challenges back in 1973.

At the time Taiwan’s export economy was made of agricultural products like sugar and simple electronics - basically low-value exports.

The government was tired of low-value agricultural exports and wanted to overhaul the economy so high-skilled exports could become a viable option.

The Economic Ministry of Taiwan was actively looking for investment in areas which could overturn the Taiwanese economy.

Even as early as the 1960s, Taiwan was working on producing low-cost electronic components. The country didn’t even have trained professionals for the semiconductor business.

In 1965, the Taiwanese government wanted to shift its focus to consumer electronics as part of the government’s policy to improve the economy.

By 1970 it was pretty clear to the Taiwanese government that the semiconductor industry would be significant going forward.

This was because of government-led seminars which included experts working in Bell Labs, IBM and other companies working on semiconductor technology.

The Ministry of Economic Affairs for Taiwan set up the Industrial Technology Research Institute (ITRI), a research institute aimed to acquire and transfer new electronic technology to the private sector.

This shows the Taiwanese government’s intent to manufacture consumer electronics built on cutting edge technologies.

The Building Stone

Right from the very start, the Taiwanese government was clear about its goals. They wanted to build a competitive semiconductor industry.

And building an industry that would be respected among its peers out of basically nowhere was a challenge and the government at the time knew it well.

The Industrial Technology Research Institute (ITRI) set up by the government had to focus on applied research instead of just basic research.

The public funded research institute had to do applied science research and its projects would be made up into separate companies.

ITRI created a sub-committee (IRSO) to teach the Taiwanese people how to build competitive semiconductor technology by learning from experts from the US, Europe and other areas.

Basically, the government tried their best to encourage semiconductor technology transfer from established companies around the world.

But the government was conscious from the very start that it had to focus on applied research with public-private partnership to be successful in chip manufacturing.

The partnerships were aimed to transfer not just the science and technology that goes behind building semiconductors.

But it also included things like management that goes in successful companies that used to build cutting-edge semiconductors at the time.

The American company RCA partnered with the Taiwanese government but the technology they shared with the Taiwanese was a couple generations behind.

United Microelectronics Corporation

You might think that TSMC was Taiwan’s first semiconductor success but that’s not the case. That crown goes to United Microelectronics Corporation (UMC), a company just a couple of blocks away from TSMC’s HQ.

In 1980, The company was spun off as a research project from IRSO and it quickly became a profitable company manufacturing semiconductors.

UMC acted like a traditional chip-maker at the time. The government provided technology, trained professionals and helped the company hit the ground running.

UMC soon became Taiwan’s most profitable industrial manufacturer of semiconductors but it failed to be a success like TSMC.

But soon, UMC started having issues, the biggest issue was that it lagged in technology against the cutting-edge chip makers of the time.

That’s why UMC mostly built low-level chips for toys and watches. It was simply not possible for UMC as a company to compete with the cutting-edge companies of the time.

The Morris Chang Story

Morris Chang, the founder of TSMC has a fascinating story. He was born in China and his parents had to flee to Hong Kong because of many wars.

He was accepted by Harvard and he went there with an interest in humanities and literature but was asked by his father to do engineering because of good career prospects.

I guess Asian parents back then still knew of engineering and medicine as the only two career options ;)

With a masters from MIT and failing the MIT PhD entrance exam twice he started looking for work. He started in a small electric company that made transistors, Morris worked for Texas Instruments for more than 20 years.

Early on when he joined Texas Instruments, he helped increase production yield to more than 30% while there. Seeing the promise in him, TI paid for his 3 year PhD at Stanford.

He helped Texas Instruments start a new fab that had circuit yields of 40%. At that time, Texas Instruments’ existing fabs had a yield as low as 20%.

After this he gets promoted to Vice President, that’s when office politics came to into play and Morris wasn’t having it. He resigned soon after, joined General Instrument for some time and left on request of the Taiwanese government to ITRI.

TSMC Enters The Chat

Taiwan Semiconductor Manufacturing Company (TSMC) was different from UMC in a couple of aspects. The company started with better technology than UMC.

This gave the company a head start right from the beginning. The technology TSMC used came from Europe from companies like Philips.

Initially, the Taiwanese government provided capital for TSMC but it knew that private input was required for success.

That’s why the company encouraged foreign investors and ‘ordered’ some of domestic business tycoons to invest in TSMC.

Most of the tycoons were old people who didn’t understand or see potential in investing in these new technologies. Still, the government was adamant.

TSMC was different from UMC because UMC thought that it would meet the domestic demands of Taiwan and that made it somewhat comfortable.

For TSMC, it had global ambitions and right from the start it wanted to compete with the world.

This was also a reflection of their Founder and CEO Morris Chang. His life was spent working in American semiconductor firms.

He was schooled by notable American universities and that also played a part in TSMC’s ambitions of being globally competitive in the chip making business.

Another major strong-point of TSMC was that it adopted the first foundry model where it only focused on the chip manufacturing and did not venture into chip design.

This was an innovative model that really paid in the long run. It was the reason companies like Nvidia, Apple are customers of TSMC.

Because through this model the company isn’t working against its partners but rather focusing on something they do best - manufacturing chips.

TSMC was a result of the Taiwanese government’s focus on replicating the American Silicon Valley model. Taiwan built its own tech valley - Hsinchu Science Park

From early on, the government facilitated research, talent acquisition, partnerships, housing for the semiconductor industry.

The government’s model was focused on applied research with projects that were spun off as small individual companies with the government being a significant investor in them.

But once the companies held their ground the government didn’t provide unnecessary subsidies or try to shield them from competition.

The government did not play favorites when it came to Taiwanese companies that made semiconductors but it did save the industry as a whole because of these steps.

And these steps not only saved the homegrown chip makers but it cemented Taiwan as the global shop for chip making that not outpaces the world in not just technology but semiconductor business.

How TSMC Leads the Industry

It is safe to say that TSMC is the foundry of the world. Its clientele includes giants like NVIDIA, Apple AMD, Intel, AMD, and many others. You don’t get these companies as your clients unless you have solid products

Having this global and top portfolio of clients is also one of the reasons that has kept the company on its toes and innovate relentlessly and continuously. That’s what has made TSMC competitive against all other foundries.

Making semiconductors itself is a serious job and creating the leading-edge semiconductors means you have to be at the top of your game.

Just for reference, a cutting-edge chip about 20 years ago would take approximately 600 steps done right. Just imagine how unforgiving today’s standards of chip making are.

Pure-Play Foundry Model

Chip making is a crazy difficult process (I mean it!). It involves hundreds of stages with most of them requiring atomic-level precision.

But largely we can divide chip making into 3 stages. That are:

Chip Design - That’s the blueprint containing details of the chip down to the transistor level

Chip Manufacturing - That’s where the blueprint comes to life on a physical node

Chip Assembly - Assembly is where companies cut down the big wafers, attach required attachments and package them

TSMC wasn’t the first company to invent semiconductors. Before it, many other companies were successful in building and selling chips.

Companies like IBM, Intel, Texas Instruments were making chips for a lot longer than TSMC. Actually, the TSMC founder himself worked for Texas Instruments for 25 years.

Fun Fact: TSMC’s founder Morris Chang was denied a promotion to the President of Texas Instruments. He resigned, and while he was unemployed, the Taiwanese government made him an offer to set up a chip making company....and the rest is history.

TSMC’s founder worked at Texas Instruments for more than two decades. He was among those who had seen this industry closer like quite few.

He realized that semiconductor manufacturing is a big challenge for most of the companies that were investing in it at that time.

You need the most complex machines to build chips, along with the cleanest rooms in the world to use those machines. On top of that you need extraordinary management for operations.

For most companies working on semiconductors at that time this investment wasn’t going to work. You need a lot more focus on a lot of things just to build a chip.

That’s where Morris realized that it’s a good idea to just focus on chip manufacturing and be the best in it. This meant that TSMC wouldn’t design or sell their own chips.

And this decision is among the most significant decisions that made TSMC a global player. This means that TSMC can now partner with chip companies without worrying about designing and assembling their own chips which are huge stages on their own.

By keeping the focus entirely on chip manufacturing TSMC was able to partner instead of just compete with chip manufacturers at the time.

Most companies of the time were trying to do all three stages of chip making and TSMC was just doing one and doing it right.

This shift of focus gave TSMC the time to focus on improving their yields and manufacturing process as much as they possibly could while other companies were trying to juggle multiple stages of chip making.

Because of TSMC’s unique business model of just focusing on chip manufacturing, it started a trend of “fabless” companies. These companies just designed their chips and outsourced manufacturing to companies like TSMC.

This, in a way, democratized the technology of chip manufacturing across companies. Nvidia, AMD, Qualcomm, all of them are fabless companies and they are at the top of their game when it comes to their market segments.

Nvidia is also a good example here that shows that you don’t need to do chip manufacturing yourself to be successful in selling great products, or becoming the most valuable company in the world (by market cap).

Because of TSMC’s focus on just the chip manufacturing, they are able to manufacture for entire companies like Apple, Nvidia, AMD and many others that don’t need to invest in their foundries.

The companies that outsource chip manufacturing to TSMC get the most advanced chips that even those companies cannot manufacture themselves.

AMD used to manufacture their own chips with GlobalFoundries but failed and now outsources manufacturing to TSMC, Intel is struggling. Smart ones like Apple and Nvidia never tried. That way they focus on what they do best while TSMC does what it does best.

So, TSMC was able to use their unique business model as one of its greatest strengths. This Pure-Foundry model helped them innovate in chip manufacturing like no other. It also helped them win clients who didn’t have to compete with another company that designs and makes its own chips. All of this led to TSMC’s.

Cutting-Edge Process

Semiconductor chips are made of transistors. They are microscopic level electrical switches that work together to form sequential logic that our computers use to play cat videos.

In Chip making, a smaller transistor size is better. If your chips are smaller in size that means you can pack more transistors on a single chip which in-turn means faster chips that are more powerful and are much more efficient. The size of an individual transistor is measured in nanometers (one billionth of a meter).

Fun Fact: Modern chips have tens to hundreds of billions of transistors. Just imagine the billions of transistors you’re carrying inside your smartphone. Doesn’t it blast off your mind with wonder?!

Because of their stable volume production with high yields the company has been successful in incrementally improving their yields using newer methods of manufacturing. TSMC’s share is 6-8x that of its closest competitors in some chip making segments.

An important factor in a foundry’s success is the production yield and TSMC’s case, it outpaces other foundries in yield. It has been able to do so because TSMC has been quick to adopt advanced manufacturing techniques like EUV lithography.

Even when companies like Samsung who design and manufacture their own chips went with GAAGET - a new and complex chip process, TSMC stayed with FinFET for its 3nm nodes and still delivered better yields than Samsung.

Intel also tried to introduce new design processes for their newer chips but the company struggled with the execution and had to make internal roadmap transitions while TSMC continued to deliver according to their roadmaps.

Another factor of TSMC’s success is their manufacturing maturity at execution mastery. Because they’ve been doing this for the longest, the company has a consistent track record of hitting production targets while offering higher production yield than others.

TSMC’s long history and a consistent track record of better yield while using cutting-edge manufacturing processes has presented it as a chip manufacturing success. They’ve been in the game of sole chip manufacturing for longer than most even though they are not the oldest chip company.

At the moment, while TSMC is working with 3nm that many other companies struggled to adopt, they’re already thinking ahead and working on the 2nm process that they aim to produce sometime next year.

This shows the company’s relentless pursuit of production technology and not stopping for anything when it comes to advanced chip manufacturing.

Customer Lock-in

The way TSMC’s business model operates makes their customers feel safe. They know they are not working for a chip maker like Samsung that would start designing their own chips one day.

TSMC’s execution history is something their customers can rely on. When it comes to advanced chip manufacturing TSMC’s first-to-market model provides them with the largest pool of initial orders.

The high-volume orders from large clients like Nvidia, Apple provide a stable and steady revenue that is perfect for early feedback to perfect the current process and fund the next one in terms of R&D.

This is one of the largest moats (strengths) for TSMC that is hard for other competitors to compete with because their products have lower yields and those companies are less trusted in execution.

Another perspective to see this customer lock-in is that chip manufacturing is already a ludicrously complex and highly capital intensive business. For a company that has been serving big fish like Nvidia and Apple for decades, it’s hard to switch for them.

Institutional Ecosystem

TSMC has collected a giant amount of institutional knowledge over 3 decades working on tens of thousands of chips for hundreds of customers.

This has provided them a precise mastery over advanced chip manufacturing processes where defects measured in parts per billion can impact yield.

The government institutions that gave birth to companies like TSMC had applied research as their motto from the very start. They wanted cutting-edge research that is proven through execution.

Initially, the Taiwanese government helped create an entire technological ecosystem for companies like TSMC for chip making knowledge transfer from foreign companies that had been doing it before them.

Early strategic partnerships between TSMC and companies like ASML - Dutch Technology giant that makes sophisticated machines that manufacture advanced semiconductors, paved the way for TSMC being competitive in chip manufacturing right from the very start which it continues to do so.

TSMC’s partnership with ASML is crucial because it is the sole provider of EUV lithography machines to TSMC. This gives TSMC a clear-edge over other foundries like some Chinese ones that can’t get access to these advanced technologies.

How Important is TSMC?

Without a doubt, Technologically, Economically and Geo-politically, TSMC is the most important company that exists in the world today. In a sense, the technological future basically depends upon TSMC.

It makes the most advanced chips that power smartphones, cloud servers that run AI, the chips inside cars and medical equipment, and even components used in defense systems

Not only is it the most mature and reputable manufacturer of chips, it is also the most advanced chip maker that heavily invests in R&D.

This investment in R&D is different from other companies because all those who contract TSMC can basically get access to this advanced technology.

Here are some of the signs that show the important of TSMC:

Powerhouse of AI and Cloud

If companies like OpenAI, Microsoft, Google, or the many others are able to offer their AI products, it is because of TSMC powering their high-performance computers.

For companies using off-the-shelf processors to custom-designed chips, they all have TSMC as their first and the largest partner for advanced chips.

If we remove TSMC from this equation that means that we basically have removed the spine that these companies operate on.

Countries Depend On It

From a geo-political perspective the future of Taiwan and superpowers like China and USA depends heavily on TSMC.

For long, China has held a claim to Taiwan and they repeatedly talk of reclaiming the small country. The USA with all its investments and dependence on advanced chips closely maintains a position to defend Taiwan.

If things escalate between the two countries we may see a conflict that has the potential to not only reach globally but also affect the global chip supply chain in a pretty bad way.

Even though TSMC makes most of the world’s advanced chips, the supply chain for a finished chip is pretty wide, ranging between multiple countries.

Any escalation on Taiwan would trigger a strong global shortage of chips impacting everything from cars, phones, computers, to every digital device being produced almost anywhere.

For Taiwan, TSMC is a geo-political lever. No industry matters more to it than its chip industry. The country’s chip industry is known as Taiwan’s “Silicon shield”.

Competitors Too Depend On It

Companies like Intel have been long time competitors of TSMC. Intel is among the few companies that have been doing complete chip making in-house, all the way from design, manufacturing and assembly.

For a long time, being able to design, manufacture and assemble chips in-house meant Intel had almost complete control over their chips. This vertical integration also provided better margins.

But today, Intel’s foundry is one of the reasons Intel is in distress. They just couldn’t keep up with advanced manufacturing of TSMC even after Uncle Sam’s 10% buyout of Intel and Nvidia’s recent $5 billion injection.

Donald Trump ordered TSMC to start manufacturing chips in the US and Intel is looking for more partnerships with TSMC to transfer knowledge on the cutting-edge processes to get back on its foot.

Since, Intel’s foundries couldn’t keep up with TSMC, they had to collaborate with TSMC to outsource part of their advanced chip manufacturing in their recent processors.

This shows that you can have a lot of money and still be not as competitive as TSMC. Intel could catch up but it would take some time for sure.

If you’re curious about why Intel’s having to outsource part of their manufacturing to TSMC, here’s a similar deep dive article on Intel that I did not long ago.

In the article below, I went into the details of the Intel’s successes and failures, it’s present and it’s future as it appears:

TSMC and the World

Although Taiwan Semiconductor Manufacturing Company has Taiwan in its name, the company’s impact is far wider than where it’s headquartered.

It’s a global company with top clients like Apple around the globe. It’s not only the largest but the most advanced pure-play foundry in the world.

This makes it uniquely positioned as a really important asset at the heart of the global semiconductor supply chain. Hurting TSMC means hurting the world.

The Global Chip Shortage that we witnessed just 5 years back showed how important chips are to the future. From consumer electronics to hospitals, all of us depend on chips.

China and the US have repeatedly spoken of Taiwan as an asset. Both countries, especially China, are rapidly modernizing their military.

We can only hope that common-sense prevails and there isn’t a conflict over the two superpowers, because once it starts no-one knows where it ends.

If things stay as they are we can hope to see TSMC continually push the boundaries and bless us with more advanced chips that power the technological future of the world all the way from AI, Robotics, Cloud, Medicine - basically everything.

Explore More

Taiwan’s dominance of the chip industry makes it more important

The Chip Titan Whose Life’s Work Is at the Center of a Tech Cold War

Morris Chang founded TSMC — the world’s most important company

Morris Chang ’52, SM ’53 describes the secrets of semiconductor success

Taiwan’s dominance of the chip industry makes it more important

Intel approaches TSMC for investments or partnership, WSJ reports